Structural adhesive failure in auto body repair is multifactorial, driven by improper surface prep, unsuitable adhesives for materials/conditions, and environmental variables like temperature and humidity. Prevention requires understanding these factors, using correct adhesives and techniques (e.g., meticulous surface preparation, primers), regular maintenance (coating, sealing), and early wear detection to ensure longevity in fender repair, bodywork, and car restoration via effective structural adhesive techniques.

“Unraveling the mysteries of structural adhesive failure is essential for ensuring the integrity and longevity of various materials and structures. This article delves into the root causes behind this critical issue, offering insights into ‘structural adhesive failure causes.’ By understanding key factors like material compatibility, environmental influences, and improper application techniques, professionals can implement effective prevention strategies. Discover proven methods to fortify bonds, enhance durability, and mitigate risks associated with structural adhesive techniques.”

- Understanding Structural Adhesive Failure Causes

- Key Factors Contributing to Adhesive Weakness

- Effective Prevention Strategies for Longevity

Understanding Structural Adhesive Failure Causes

Structural adhesive failure can be a complex issue, often stemming from a variety of factors that must be understood to prevent it effectively. When considering structural adhesive techniques, several causes commonly contribute to this problem. One primary reason is improper preparation of the surfaces to be bonded, including contamination with grease, dust, or other substances that weaken the bond. In auto body services and vehicle repair services, where precision and quality are paramount, ensuring clean, dry surfaces before application is crucial.

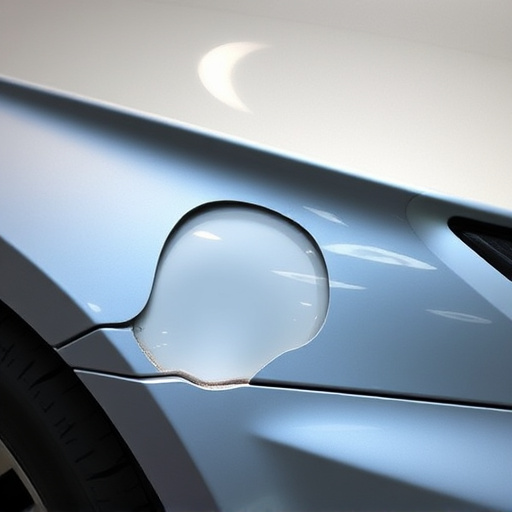

Another significant cause is the use of unsuitable adhesives for specific materials or conditions. Different substrates require different adhesive properties to form a strong bond. For instance, using an adhesive intended for metal on plastic or composite materials can lead to premature failure. Auto repair services that specialize in these diverse materials must be adept at selecting the right adhesive for each job. Additionally, environmental factors such as temperature and humidity can impact adhesive performance, with extreme conditions potentially causing curing issues and reduced bond strength, especially in vehicle repair services operating in regions with dramatic climate variations.

Key Factors Contributing to Adhesive Weakness

In the realm of structural adhesive techniques, understanding the key factors contributing to adhesive weakness is paramount for preventing failure and ensuring durability. One major culprit is environmental exposure, with excessive heat, cold, moisture, or ultraviolet radiation capable of degrading the adhesive’s properties over time. These external elements can compromise the chemical bonds within the adhesive, leading to a loss of strength and adhesion.

Another significant factor is improper surface preparation. Unclean or unpolished surfaces can hinder the adhesive’s ability to bond effectively with the substrate. Debris, oil, rust, or previous adhesive residue can all interfere with the bonding process. Thorough cleaning and surface treatment, including priming, are essential steps in ensuring a robust bond. Moreover, using the right adhesive for the specific application and material is crucial, as compatibility issues can result in weaknesses that manifest over time, as seen in cases like Mercedes Benz repair where specifc adhesives are required to match the car’s original integrity.

Effective Prevention Strategies for Longevity

Preventing structural adhesive failure is key to ensuring longevity in applications like fender repair, vehicle bodywork, and car restoration. The first line of defence involves meticulous preparation of surfaces before application. This includes cleaning, degreasing, and ensuring the presence of a clean, dry surface free from contaminants that could weaken the bond. Using suitable primer or underlayers recommended by the adhesive manufacturer can also enhance adhesion significantly.

Beyond initial preparation, regular maintenance plays a crucial role. Protecting the adhesive surface from harsh environmental conditions like extreme temperatures, sunlight exposure, and moisture is vital. Applying protective coatings or seals can shield the adhesive, preserving its integrity over time. Additionally, monitoring for signs of wear, cracking, or delamination early on allows for prompt intervention, preventing minor issues from escalating into major structural failures in applications such as vehicle bodywork and car restoration.

Structural adhesive failure is a complex issue, but by understanding its causes and implementing preventive strategies, engineers and manufacturers can significantly enhance the longevity of bonded structures. By recognizing key factors like material incompatibility, improper surface preparation, and environmental stressors, professionals can employ effective solutions such as choosing the right adhesives, ensuring rigorous cleaning protocols, and providing adequate protection from moisture and extreme temperatures. Adhering to these practices ensures the reliability and safety of structural adhesive techniques across various industries.