Monitoring the cure process in structural adhesive techniques is vital for enhancing bond strength and durability, especially in modern applications like automotive repairs with advanced composites. Techniques like infrared thermography, optical sensors, ultrasound, and radar provide real-time data, ensuring precise control over temperature, pressure, and duration during cure, leading to optimal molecular arrangements and superior structural performance.

Adhesive cure monitoring is a critical aspect of structural bonding procedures, ensuring robust and lasting connections. This article explores the dynamics of adhesive cure, delving into innovative monitoring techniques for optimal structural integrity. We analyze real-time data analysis as a powerful tool to enhance quality control, revolutionizing traditional methods in the realm of structural adhesive techniques. By understanding cure dynamics and employing advanced monitoring, engineers can achieve superior bond performance, crucial for safety and longevity in construction projects.

- Understanding Adhesive Cure Dynamics

- Monitoring Techniques for Structural Bonding

- Ensuring Quality via Real-Time Data Analysis

Understanding Adhesive Cure Dynamics

The cure process of adhesives used in structural bonding procedures is a dynamic and complex phenomenon that plays a critical role in determining the overall strength and durability of the bond. Understanding this dynamics involves recognizing the intricate chemical reactions, temperature effects, and time dependencies involved. Adhesive cure monitoring is essential to ensure these processes occur as intended, leading to optimal bond performance. By closely examining the interactions between the adhesive and the substrate, professionals can predict and control the mechanical properties resulting from the curing process.

In structural adhesive techniques, the ability to monitor and manage cure dynamics is akin to fine-tuning a precision machine. Just as a Mercedes-Benz repair service technician would meticulously inspect various components during a collision center overhaul, adhesive cure monitoring requires precise measurement of factors like temperature, pressure, and time. This ensures that adhesives reach their optimal molecular arrangement, resulting in bonds that rival the strength of the base materials themselves, be it metal, composite, or other advanced materials used in modern automotive repair services.

Monitoring Techniques for Structural Bonding

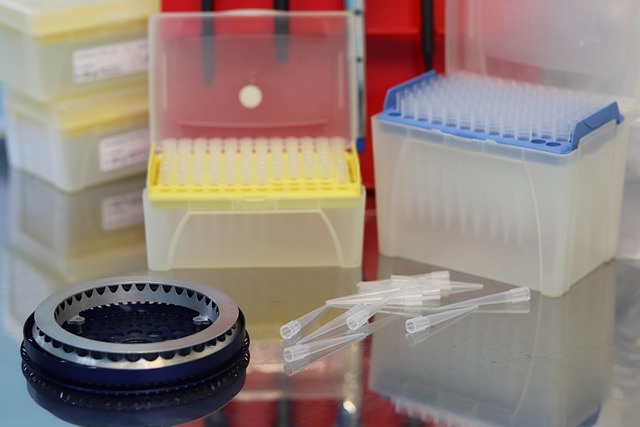

Monitoring the cure process is a critical step in structural adhesive techniques, ensuring the strength and durability of bonds. Various advanced monitoring techniques have been developed to track the progression of chemical reactions during adhesive curing. These methods include infrared (IR) thermography, which detects temperature changes, providing insights into the exothermic reaction of adhesives. Additionally, optical sensors can measure the refractive index shift, indicating polymerization progress, a technique particularly useful in automotive repair shops when conducting car paint repairs or auto glass replacements.

Non-destructive testing (NDT) methods, such as ultrasound and radar, are employed to assess bond integrity without causing damage. These tools help identify potential issues like air bubbles, voids, or incomplete curing, which could impact the overall performance of bonded structures. By integrating these monitoring techniques into structural bonding procedures, manufacturers can achieve consistent high-quality results, ensuring safety and reliability in applications ranging from automotive repairs to construction projects.

Ensuring Quality via Real-Time Data Analysis

In modern structural adhesive techniques, real-time data analysis plays a pivotal role in ensuring the quality and integrity of bonding procedures. By leveraging advanced monitoring systems, professionals in auto repair shops, including those specializing in Mercedes Benz collision repair, can gain valuable insights into the cure process. This enables them to make informed adjustments, optimize bond strength, and ultimately achieve superior structural performance. Real-time data allows for quick identification of any anomalies or deviations from the expected cure profile, ensuring that every bond meets stringent industry standards.

For instance, in luxury vehicle repair scenarios, where precision and durability are paramount, real-time analysis can help maintain consistent results. This is particularly crucial when dealing with intricate bond configurations found in modern automotive designs. With continuous feedback, technicians can fine-tune their approach, whether it’s adjusting application methods or modifying environmental conditions, to guarantee optimal adhesive cure for every repair, be it a minor fix or complex restructuring.

Adhesive cure monitoring in structural bonding procedures is a game-changer in ensuring the strength and durability of bonded joints. By understanding the dynamics of adhesive cure, employing advanced monitoring techniques, and leveraging real-time data analysis, professionals can optimize structural adhesive techniques, mitigate risks, and deliver superior bond quality. This comprehensive approach guarantees that every joint meets stringent performance standards, ultimately enhancing the overall integrity of constructed structures.