Meticulous surface preparation using solvents or cleaners and proper drying is crucial for robust bonds with structural adhesives. Techniques vary based on material types, involving deburring metal or applying primers for composites. Choosing the right adhesive for materials, conditions, loads, and strength needs is vital for reliable bonding in auto repair, as seen in Mercedes-Benz standards. Specific application methods ensure even distribution and maximum bond strength.

Maximize the strength of your structural bonds with these expert tips on structural adhesive application. This comprehensive guide delves into essential aspects, including surface preparation for optimal adhesion and selecting the ideal adhesive for your project. We explore proven techniques for applying adhesives, ensuring superior bonding results. Learn how to enhance structural integrity through effective structural adhesive techniques.

- Understanding Surface Preparation for Adhesion

- Choosing the Right Structural Adhesive for Your Project

- Applying Adhesive: Techniques for Optimal Bonding

Understanding Surface Preparation for Adhesion

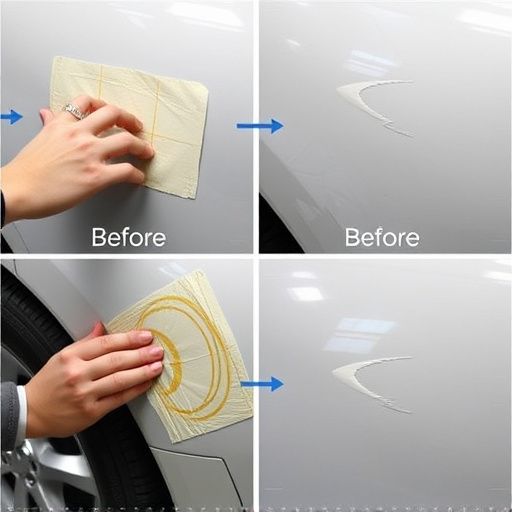

Getting a strong bond requires proper surface preparation when using structural adhesives. Before applying any adhesive, it’s crucial to clean and decontaminate the surfaces thoroughly. This involves removing grease, dust, dirt, and any loose debris. A simple cleaning process can include using solvents or specialized cleaners suitable for automotive applications, especially in collision repair shops. Once cleaned, ensuring the surfaces are dry and free from any residual moisture is essential. Proper surface preparation creates a clean canvas, allowing the adhesive to adhere firmly, which is critical for maximum strength in auto maintenance and painting projects.

Additionally, considering the material types of the surfaces you’re joining is key. Different materials have varying levels of porosity and chemical properties, impacting adhesion. For instance, preparing metal surfaces often involves deburring or using specific primers to enhance adhesion, whereas composite materials may require unique treatments. Employing suitable surface preparation techniques, as part of structural adhesive applications, ensures the integrity of the final bond, making it indispensable in any auto-related work, be it collision repair or auto painting tasks.

Choosing the Right Structural Adhesive for Your Project

When considering structural adhesive application for your project, the first step is understanding the importance of choosing the right adhesive. Different adhesives are designed for specific applications and materials, so it’s crucial to match the adhesive with your project’s unique requirements. For instance, if you’re working on an automotive repair near me or auto repair services involving complex vehicle structures, a strong structural adhesive optimized for the material and conditions is vital.

Auto repair shops often rely on specialized adhesives to ensure the integrity of repairs, which can be as critical as in building construction projects. The right choice involves considering factors such as the type of materials to be bonded (metal, plastic, composite), environmental conditions, expected stress loads, and desired bond strength. With these considerations in mind, you’ll be better equipped to select a structural adhesive that meets your project’s needs and provides maximum strength through effective structural adhesive techniques.

Applying Adhesive: Techniques for Optimal Bonding

When applying a structural adhesive for maximum strength, understanding the structural adhesive techniques is crucial. Begin by ensuring the surfaces are clean, dry, and free from any contaminants like grease or dust. This initial preparation is vital for optimal bonding. Use a primer if necessary to enhance adhesion, especially when dealing with complex geometries or varying material types, as seen in meticulous Mercedes-Benz collision repair processes at premier vehicle body shops.

For best results, employ techniques such as beading or spray application, depending on the adhesive and surface. Beading involves applying the adhesive in controlled beads along joints, ensuring even distribution for strong bonds. Spray application, on the other hand, uses a special gun to create a thin, even layer, ideal for large surfaces or hard-to-reach areas within auto body services.

Maximizing the strength of structural adhesives relies on a comprehensive understanding of surface preparation, choosing the right adhesive for your project, and employing optimal application techniques. By adhering to these guidelines, you can ensure robust bonding and enhanced structural integrity, making structural adhesive applications a reliable solution for various industrial and construction needs. Incorporating the discussed structural adhesive techniques will contribute to successful outcomes in even the most demanding projects.